MAGIS Opti

The new panel optimisation software

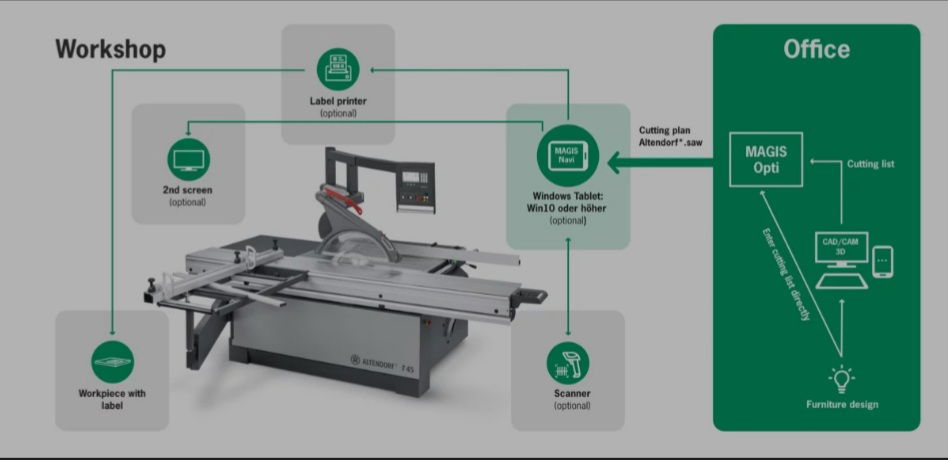

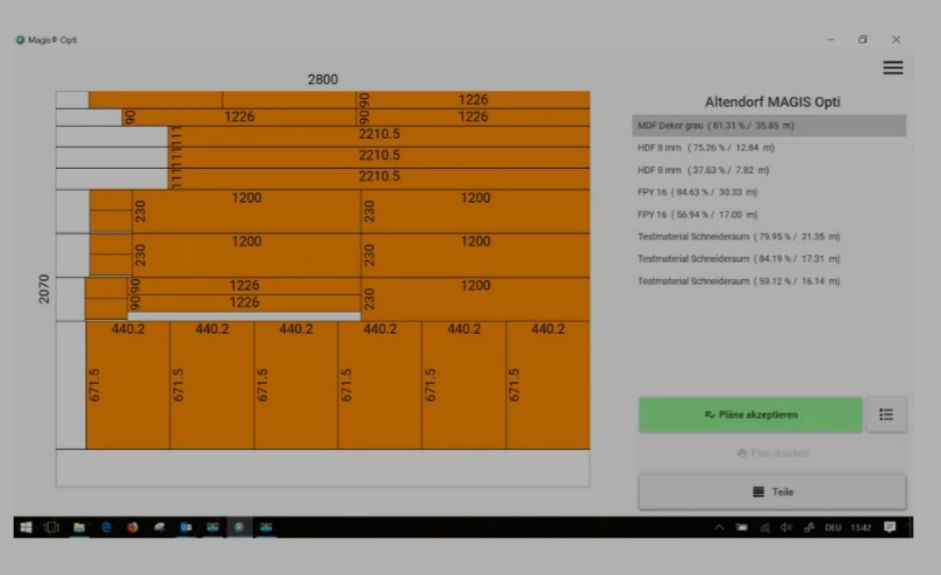

MAGIS Opti is an optimisation software for PCs and tablets that Altendorf especially developed for sliding table saws. It creates a broad range of options to meet customers’ needs and make sliding table saw operations more economical.

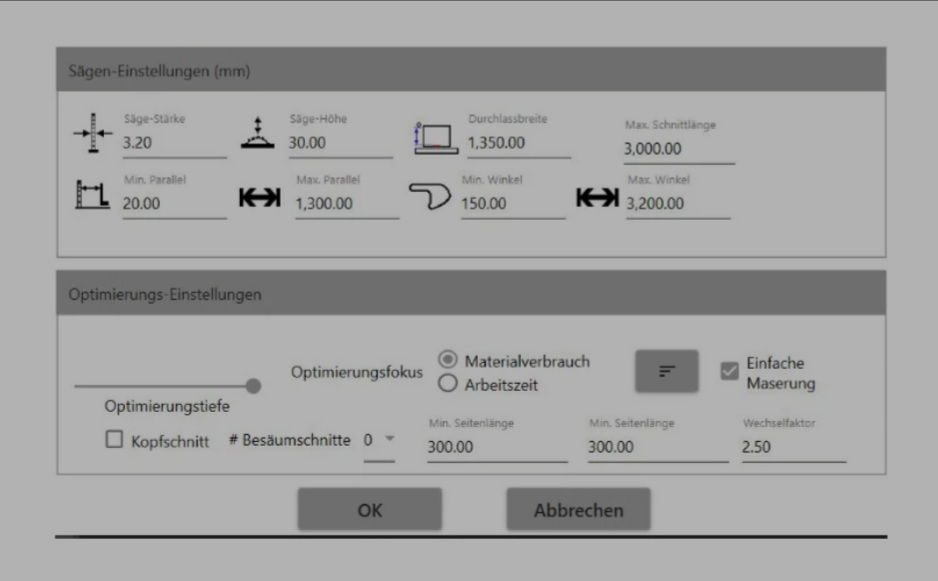

Altendorf MAGIS Opti offers a number of possibilities to meet your individual requirements. The intelligent software takes into account the parameters of your machine and calculates precisely where your workpiece can be cut. Special properties can also be assigned to the workpieces. This allows you to optimize the workpiece list for different goals such as time or waste.Required operating system: Windows 10 or higher.

How does MAGIS Opti work?

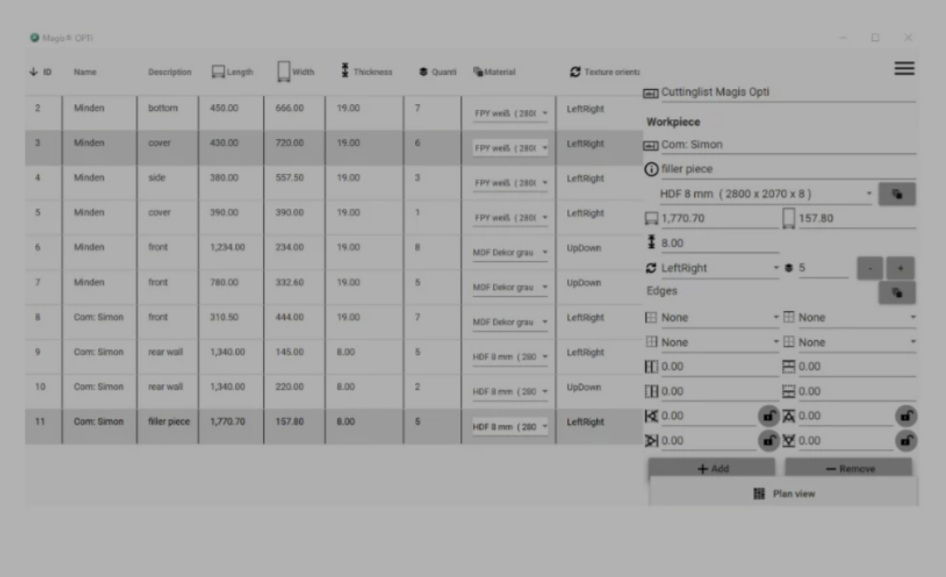

Our software supports you in optimising cutting and creates the optimal cutting plan for the existing workpiece from your list.The software for cutting optimisation offers a number of possibilities to respond individually to customer specifications and at the same time to make work preparation on the sliding table saw more economical. Import cut lists as an Excel file or create the necessary steps directly as a plan that you can edit and adjust at any time. Furthermore additional information like those required for edgebanding can also be specified here.

Altendorf MAGIS Opti at a glance:

- Material and time losses are prevented

- Entry of new cutting plans, expansion of cutting plans being carried out

- Input of machine and optimisation parameters

- Input of material and processing properties

- CSV interface for data import and export

- Structured storage of the cutting plan in the end-customer folder

- Creation of barcodes and PDF overview plans for material procurement

- Inclusion of a label-generating tool

Altendorf MAGIS Opti in Detail

Optimised work preparation

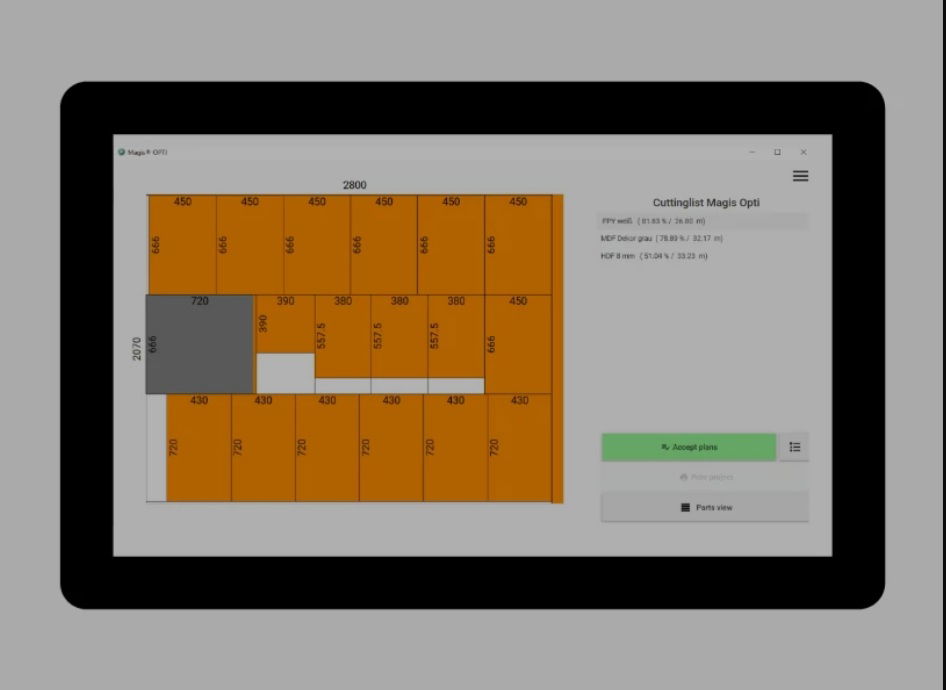

Every cutting plan begins with furniture design. You face your first challenge when you put together your cutting list. After all, you want to save the most time and material as possible. So a number of questions then arise: How much material do we need? How can the individual components be reasonably spread out on the panel? In what sequence should the parts be cut?Thanks to MAGIS Opti, you no longer have to think twice about such questions. The smart software will do the work for you!

Individual cuts to meet customers’ needs

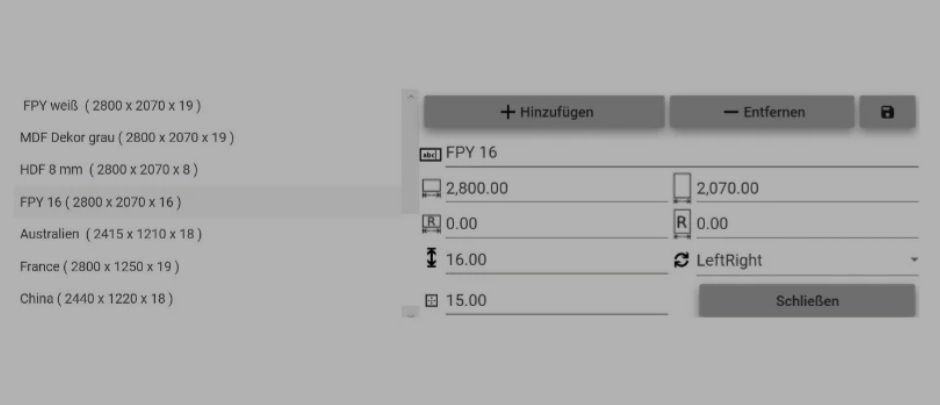

The individual parts can be input into MAGIS Opti directly in table form. Special characteristics like type of material and the direction of the natural grain or other special features can be assigned to the workpieces. Afterwards, the workpiece list can be determined with such objectives as time and waste wood. Other settings like stacking and offcut sizes can further optimise the result.

Consideration of machine parameters

One major strength of MAGIS Opti is its ability to consider the most important parameters of sliding table saws. Working in the background, the software determines the fence on which the material can be cut. As a result, you can work very efficiently on your machine.

The cutting plan can also be directly scanned into the F 45 ElmoDrive control unit or the MAGIS Navi.

Faster and smoother production process

To ensure fast, smooth production operations, MAGIS Opti provides the option of workpiece identification. Information about edgebanding, bevel cuts or oversize can be entered into the workpiece list and printed on the label later if necessary. The workpiece then becomes unique. A bevel and material database is also integrated into the software. Here you can store the most important data about material and bevel processing for your production operations and retrieve it at any time.