HOMAG Model: KFL 526/9/A3/25

Technical details:

- CE mark - Numerical Control POWER CONTROL PC 22 (software on Windows bases)

- To apply (straight edges) thin bands and PVC/ABS bands up to 3 mm thickness

- It is possible to edge band panels inclined of 4°

- Useful both as first and second machine in a line (it can receive panels up to mm 1200

approx. depth) - Max opening mm 2500

- Max thickness of the panel mm 60

- Adjustable feeding speed up from 15 to 40 m/min

Machine equipped with the following units (per each machine's side):

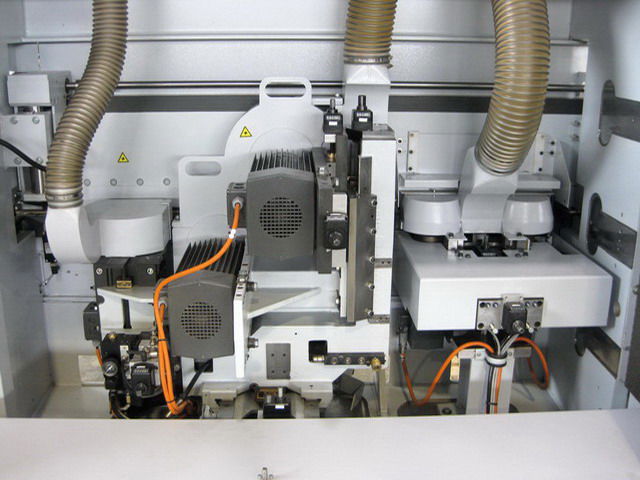

SQUARING PART:

- 1 Milling Unit (anti-chipping) with pneumatic control (KW 4.5 x 1 at RPM 6000)

- 1 Bottom Hogger (KW 6,6 x 1 at RPM 9000)

- 1 Top Hogger (KW 6,6 x 1 at RPM 9000)

- Twin (2) milling / joint trimming unit UF20 (KW 4 x 2 motors at RPM 9000), electro-pneum.

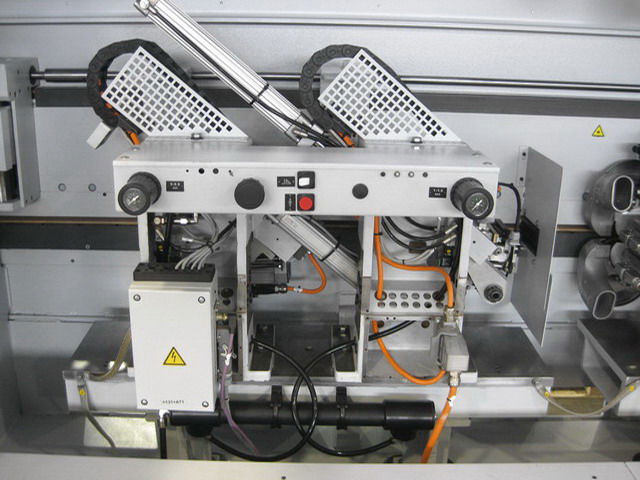

BANDING PART:

- Glueing Unit A3 (Hot Melt glue) with glue pot, Quick Melt system, Edge coils supporting unit

(with 2 coils), pressure rollers, all tiltable 0°-5°, also to edge band panels inclined of 4°

- End-cutting unit HL81 (kW 0,22 x 2 at RPM 12000), swivelling 0°-30°

- Overlapped trimmers (KW 0,55 x 2 at RPM 12000)

- Fine trimming unit (KW 0,4 x 2 at RPM 12000 RPM), tilting 0°-25°

- Multi function Units FK 11 (KW 0,4 x 2 at 12000 RPM) for top & bottom fine-trimming and front & rear corner rounding process, with manual fast-release tools changing system

- Profile scraping unit PN20

- Finishing Units FA 10, with glue scraper (with Predisposition to add the buffing units)